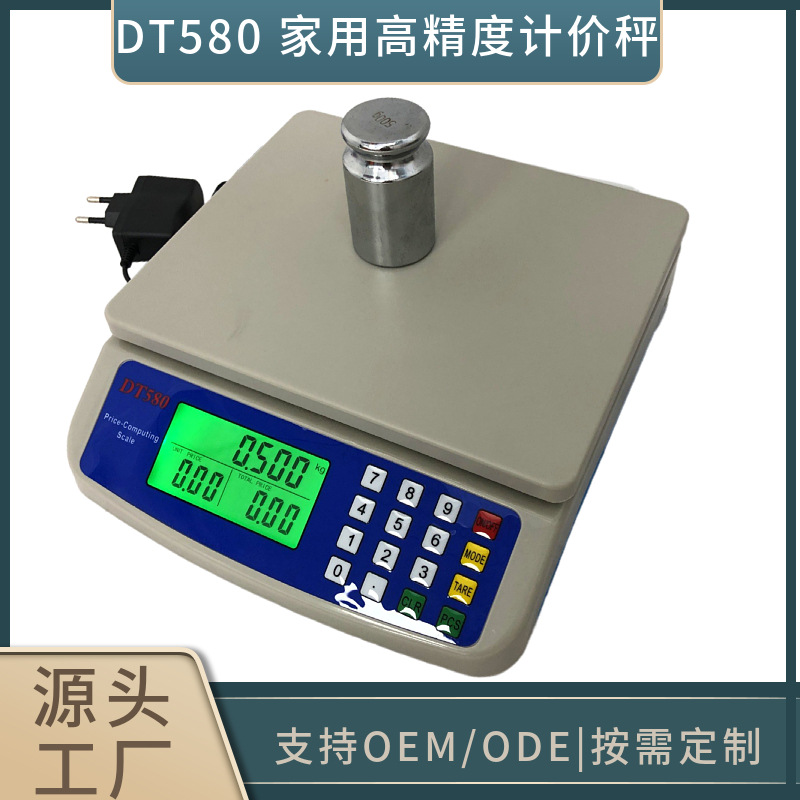

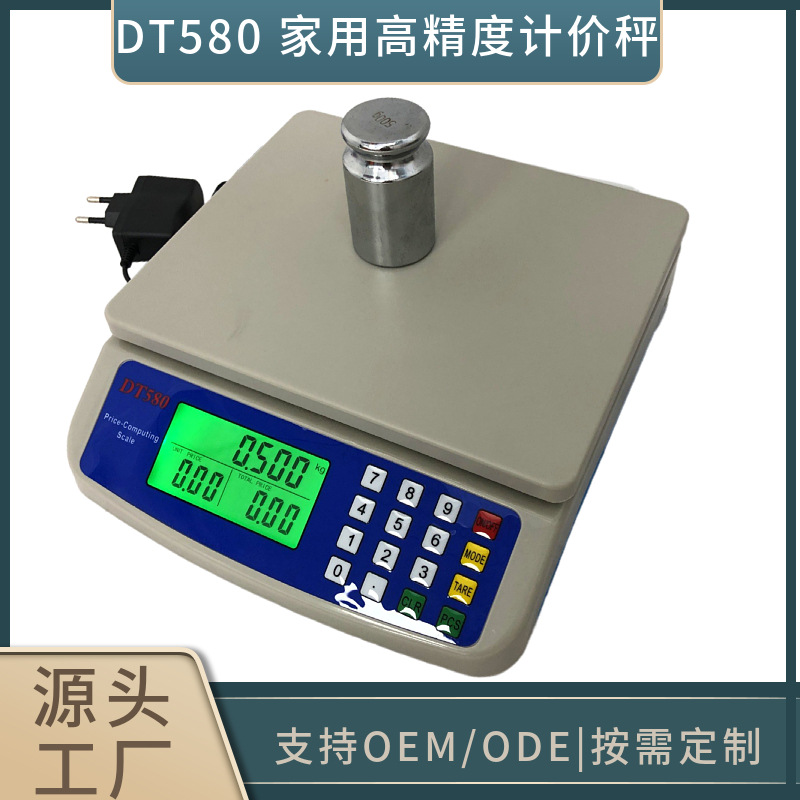

Buy Direct from Manufacturers: Accurate Electronic Kitchen Scale for Vegetables & Fruits

In the fast-moving world of international fruit and vegetable trade, every gram counts — not just in weight, but in trust, transparency, and total value. That’s why more exporters, packers, and small-scale farmers are turning to a smarter sourcing model: buying directly from manufacturers. No middlemen. No inflated prices. Just reliable, high-performance tools built specifically for the demands of fresh produce logistics.

Breaking the Chain: Why Manufacturer Direct Supply Is Reshaping Global Procurement

Traditional supply chains often add layers of markup — distributor fees, regional agent commissions, warehousing costs — that quietly erode profit margins. When you purchase an electronic kitchen scale through conventional channels, up to 40% of what you pay may have nothing to do with the product itself. By contrast, going straight to the source slashes these unnecessary expenses. More importantly, it accelerates response times. Need a bulk order customized? Want technical support fast? Direct manufacturer access means quicker communication, faster production cycles, and greater control over quality assurance.

This streamlined approach isn’t just about saving money — it’s about gaining agility. For exporters managing tight shipment windows or seasonal harvests, having immediate access to durable, accurate weighing equipment can make the difference between meeting compliance standards and facing costly delays.

Precision Beyond the Gram: The Unseen Role of Accuracy in Fresh Produce Trade

When dealing with perishable goods like berries, herbs, or exotic fruits, even minor discrepancies in weight can lead to major financial losses over time. Our manufacturer-direct electronic scale features imported sensors capable of detecting changes as slight as 1g, with stable readings up to 30kg. Whether you're portioning delicate leafy greens or loading crates for export, this level of consistency ensures fairness, regulatory compliance, and customer confidence.

The scale’s rapid response and automatic zero-return function eliminate drift during continuous use — essential when processing hundreds of units per day. In environments where speed and accuracy go hand-in-hand, such reliability becomes a silent partner in operational excellence.

Designed for the Real World: Where Engineering Meets Everyday Needs

This isn’t a one-size-fits-all gadget. Every design choice reflects deep insight into real-world usage. The waterproof stainless steel platform withstands daily washdowns and humid packing areas without corrosion. The large 215×175mm weighing surface accommodates bulky items without tipping risks. And with seamless switching between kg, lb, and catty, the scale adapts effortlessly to diverse international markets — from North American supermarkets to Asian wet markets.

Power flexibility is another game-changer. Use two AA batteries for mobility, or plug directly into power for uninterrupted operation during peak shifts. An auto-shutdown feature conserves energy, while overload and low-voltage alerts protect both device and operator. Built to last, the DT-580 model combines lightweight portability (just 890g net) with industrial-grade resilience.

More Than a Tool: Building Brand Trust Through Consistent Measurement

In today’s transparent marketplace, credibility is currency. Consumers and B2B buyers alike demand traceability and honesty in labeling. A precise, consistently calibrated scale acts as an invisible seal of integrity — much like organic certification or third-party inspection reports. When every batch is weighed with the same trusted instrument, your brand sends a powerful message: we measure fairly, we deliver accurately, and we stand by our numbers.

For small farms entering global markets, this consistency can be a decisive competitive edge. It transforms a simple transaction into a relationship built on reliability — laying the foundation for long-term partnerships and repeat orders.

The Hidden ROI of Smart Equipment Investment

At first glance, a $20–$30 scale might seem like a minor expense. But multiply that across dozens of units in a large facility, and consider the hidden costs of downtime, recalibration, or inaccurate shipments. Low-quality scales fail faster, require frequent replacements, and introduce errors that ripple through inventory and invoicing systems.

By investing in a durable, manufacturer-backed solution, businesses reduce maintenance hassles, minimize waste due to misweighing, and ensure smoother audits and inspections. Over time, these efficiencies compound — turning a modest upfront investment into significant operational savings.

The Future of Weighing: Intelligence Built In

While today’s model delivers unmatched value in accuracy and durability, tomorrow’s iteration promises even greater integration. Imagine Bluetooth connectivity syncing weights directly to cloud-based inventory platforms, or multi-language interfaces supporting teams across continents. These aren’t distant dreams — they’re logical evolutions already taking shape in next-gen prototypes.

By partnering with forward-thinking manufacturers now, businesses position themselves at the forefront of digital agriculture and smart food logistics. The humble kitchen scale is no longer just a tool — it’s becoming a node in a connected ecosystem of trust, traceability, and efficiency.

Ready to upgrade your weighing process with a proven, manufacturer-direct solution? Experience the difference that true precision, thoughtful design, and direct sourcing can bring to your fresh produce operations.